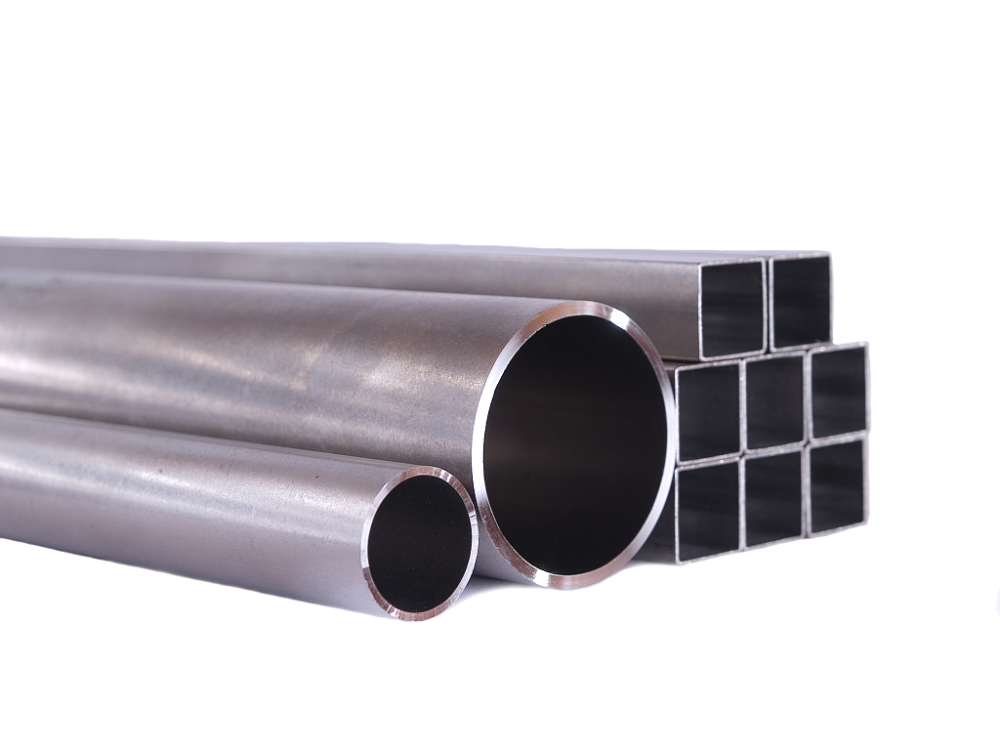

Hollow Section

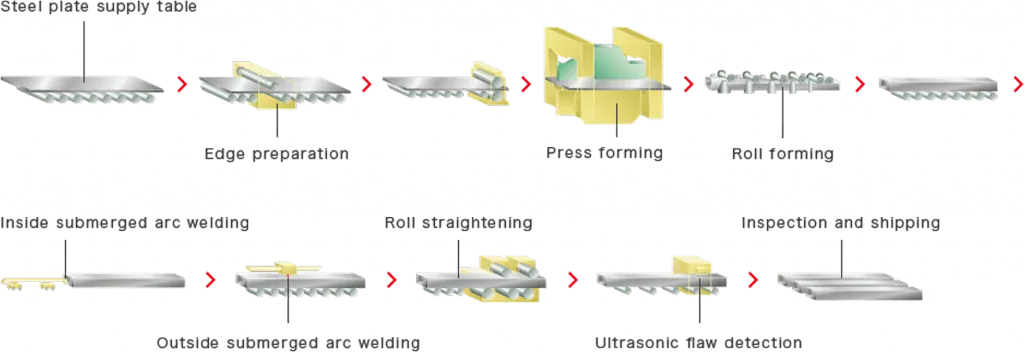

“Hollow section” (HSS: Hollow Structural Section) refers to a structural shape with a hollow section, usually made of steel. It has the properties of steel, such as high strength, stiffness and corrosion resistance.

In manufacturing and construction, a hollow section is a hollow steel tube or profile. It can be round, square, rectangular, or another shape. This structural shape of tubes or profiles is commonly used in a variety of engineering and construction projects. such as used in components or structures made of metal, plastic, concrete, etc.